-

The Tools of Production

In order to keep production at such a pace—building up to more than 100,000 planes a year—the tools were critical. These tools had a few requirements: to make machines of war, they needed to forge metal; they needed to produce large quantities quickly; and they needed to produce many complicated parts.

Fred Geier, president of the Cincinnati Milling Machine Company, reported that they produced a new machine tool every 17 minutes during the war, thereby nearly doubling machine tool production before the end of 1941. -

The key to building planes, tanks, guns, ships, jeeps, and trucks on assembly lines would be machine tools—those that grind, bore, shape and mold metals. Depending on the job, a machine tool might range from the size of a toaster to that of a house.

Handheld drills allowed multiple workers to work on a single section of aircraft or ship’s hull at a time. This drill was used by Milton L. Donnell Sr., an employee at the Higgins Industries plant in New Orleans. Donnell worked on several vessels, but primarily built the critical LCVP. Gift of Norma B. Donnell.

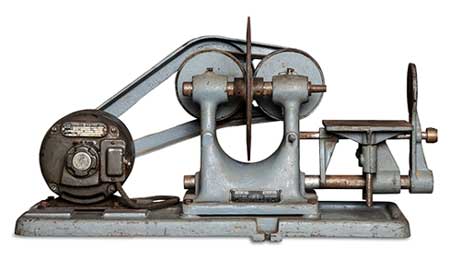

Handheld drills allowed multiple workers to work on a single section of aircraft or ship’s hull at a time. This drill was used by Milton L. Donnell Sr., an employee at the Higgins Industries plant in New Orleans. Donnell worked on several vessels, but primarily built the critical LCVP. Gift of Norma B. Donnell. This tapping machine was used to thread the necks of hand grenades. Gift of Scott Carroll.

This tapping machine was used to thread the necks of hand grenades. Gift of Scott Carroll. Burners performed an important role in shipbuilding by prepping and finishing welding surfaces. Protective eyewear shielded burners from the blinding light of sparks. These goggles belonged to Rose Rita Samona, a burner at Delta Shipbuilding Company in New Orleans, which produced 188 critical supply vessels known as Liberty ships. Gift of Rose Rita Samona.

Burners performed an important role in shipbuilding by prepping and finishing welding surfaces. Protective eyewear shielded burners from the blinding light of sparks. These goggles belonged to Rose Rita Samona, a burner at Delta Shipbuilding Company in New Orleans, which produced 188 critical supply vessels known as Liberty ships. Gift of Rose Rita Samona. -

Welders were absolutely critical to the war effort; their skills helped to make everything from heavy bombers to aircraft carriers. This mask and these gloves protected Philip Louis Giroir Sr. while he worked as a welder at Delta Shipbuilding Company. Gift of Ronald Giroir.

Welders were absolutely critical to the war effort; their skills helped to make everything from heavy bombers to aircraft carriers. This mask and these gloves protected Philip Louis Giroir Sr. while he worked as a welder at Delta Shipbuilding Company. Gift of Ronald Giroir.

Welders were absolutely critical to the war effort; their skills helped to make everything from heavy bombers to aircraft carriers. This mask and these gloves protected Philip Louis Giroir Sr. while he worked as a welder at Delta Shipbuilding Company. Gift of Ronald Giroir.

Welders were absolutely critical to the war effort; their skills helped to make everything from heavy bombers to aircraft carriers. This mask and these gloves protected Philip Louis Giroir Sr. while he worked as a welder at Delta Shipbuilding Company. Gift of Ronald Giroir. -

The resulting products were state-of-the art, precise, and complicated. The arrival of machine tools dramatically increased productivity and played a key role in escalating aircraft production, in particular, which was an incredibly complicated process due to the large number of parts involved. Next

Boeing’s B-29 Super Fortress Bomber was a machine of great magnitude. A total of 3,970 B-29s were produced during the war, and each contained more than 165,000 individual parts. Courtesy of Boeing.

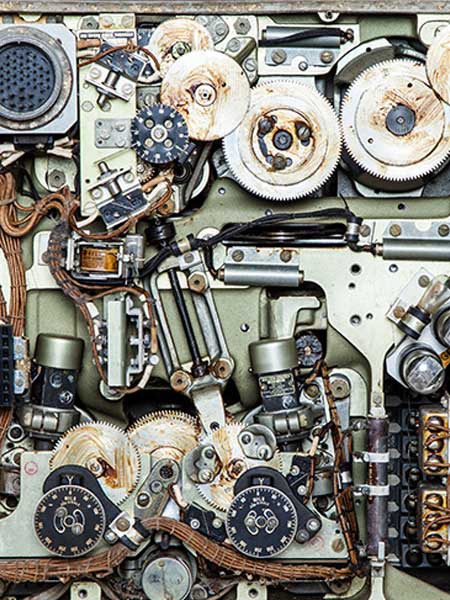

Boeing’s B-29 Super Fortress Bomber was a machine of great magnitude. A total of 3,970 B-29s were produced during the war, and each contained more than 165,000 individual parts. Courtesy of Boeing. The B-29 Bomber, designed to fly extremely long-range bombing missions, needed to defend itself if attacked. To aid in this defense, each gun position was equipped with one of the first computers carried on board an aircraft. This particular unit was used by the gunner and bombsite operator located in the nose of the plane. Gift in Memory of Norman Dedeaux, USMC.

The B-29 Bomber, designed to fly extremely long-range bombing missions, needed to defend itself if attacked. To aid in this defense, each gun position was equipped with one of the first computers carried on board an aircraft. This particular unit was used by the gunner and bombsite operator located in the nose of the plane. Gift in Memory of Norman Dedeaux, USMC. The Pratt & Whitney Twin Wasp R-1830 Radial Engine powered dozens of aircraft, including the B-24 Bomber and C-47 Skytrain. As a result, it became the most heavily produced aviation piston engine in history, with more than 170,000 units being produced throughout its production life. Gift of Pratt and Whitney.

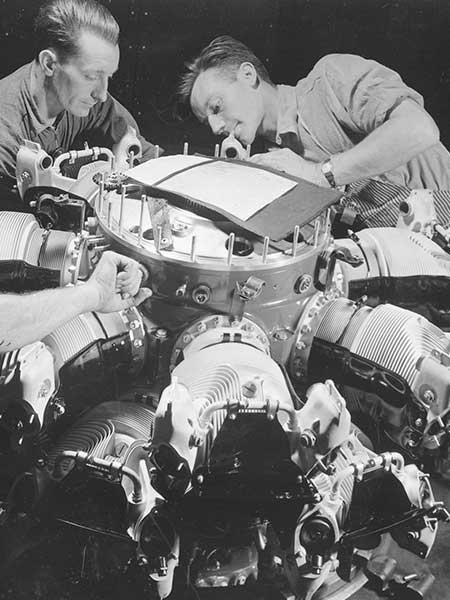

The Pratt & Whitney Twin Wasp R-1830 Radial Engine powered dozens of aircraft, including the B-24 Bomber and C-47 Skytrain. As a result, it became the most heavily produced aviation piston engine in history, with more than 170,000 units being produced throughout its production life. Gift of Pratt and Whitney. Workers install cylinders on a new Pratt & Whitney radial aircraft engine in 1942. Courtesy of National Archives.

Workers install cylinders on a new Pratt & Whitney radial aircraft engine in 1942. Courtesy of National Archives.

-

Share on Facebook

-

Share on Twitter

Tweet -

Share on Tumblr