-

Industry & Innovation

In May 1940, Roosevelt’s call for 50,000 planes was ridiculed. By 1944, through Knudsen's increase in government contracts, plants in the United States were producing nearly 100,000 planes annually. The wartime total of more than 300,000 planes exceeded the production of Britain and the Soviet Union combined.

-

“Victory Is Our Business” (1942). This motivational film from General Motors emphasizes its massive production effort—making everything from engines to ammunition to aircraft—while trumpeting the speed and innovation with which they were made.

-

One thing made these incredible numbers a reality: Innovation.

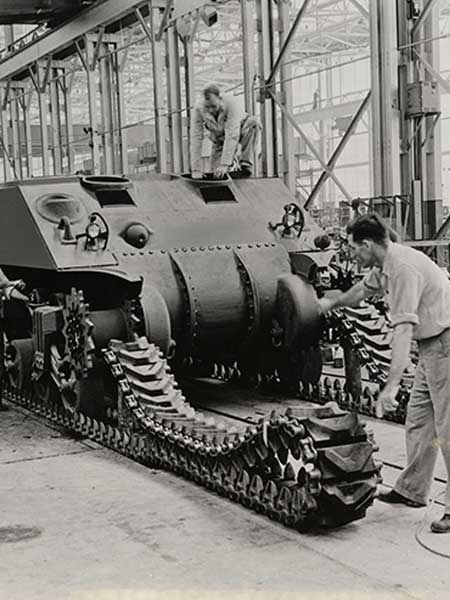

Architect Albert Kahn designed two of the first plants built expressly for the mass production of war machinery: Chrysler’s Detroit Arsenal Tank Plant and Ford’s Willow Run Bomber plant. Industrialist Henry Kaiser reached record production of Liberty ships through innovative subassembly techniques, and provided revolutionary health coverage for his employees. Many companies, such as LeTourneau, converted peacetime products to wartime use. Still others ramped up existing production as never before. The Detroit Arsenal Tank Plant required extensive open floor space. Such space allowed tracks to be installed right on the factory floor. Courtesy of the National Automotive History Collection, Detroit Public Library.

The Detroit Arsenal Tank Plant required extensive open floor space. Such space allowed tracks to be installed right on the factory floor. Courtesy of the National Automotive History Collection, Detroit Public Library. Willow Run Bomber Plant under construction in 1940. Once complete, the aircraft plant featured an assembly line more than a mile long. Photo courtesy of MLive.com/Landov.

Willow Run Bomber Plant under construction in 1940. Once complete, the aircraft plant featured an assembly line more than a mile long. Photo courtesy of MLive.com/Landov. LeTourneau produced mostly farm and light industrial equipment before the war, but many of the company’s designs worked well in combat engineering roles. Photo courtesy The R.G. LeTourneau Museum and Archives, The Margaret Estes Library, LeTourneau University.

LeTourneau produced mostly farm and light industrial equipment before the war, but many of the company’s designs worked well in combat engineering roles. Photo courtesy The R.G. LeTourneau Museum and Archives, The Margaret Estes Library, LeTourneau University. Harley-Davidson produced more than 90,000 motorcycles for the military during WWII. Courtesy of Harley-Davidson Archives.

Harley-Davidson produced more than 90,000 motorcycles for the military during WWII. Courtesy of Harley-Davidson Archives. -

One of the motivations to push hard in production was the possibility of earning recognition through "E" for Excellence awards. The Army and Navy presented these tokens to acknowledge outstanding levels of production. To receive one of these awards was a great source of pride and a symbol of a company's and individual's contribution to the war effort.

Lura Chesteen Sanders Ware worked as an armament inspector at Gulf Ordnance Plant, Proctor and Gamble Defense Corporation in Aberdeen, Mississippi. She and each of her coworkers received a certificate like this at a ceremony held on April 27, 1944. Gift of Linda White.

Lura Chesteen Sanders Ware worked as an armament inspector at Gulf Ordnance Plant, Proctor and Gamble Defense Corporation in Aberdeen, Mississippi. She and each of her coworkers received a certificate like this at a ceremony held on April 27, 1944. Gift of Linda White. -

Not only did the means of production break new ground, but the products that these businesses and processes made were innovative, as well. Take, for example, the boat design shipbuilder Andrew Higgins invented that was used to storm the beaches of Normandy, or the first hand-held communication device from Motorola, or the first chocolate that wouldn't melt in high temperatures.

New Orleans shipbuilder Andrew Higgins would later be credited by General Dwight D. Eisenhower as the “man who won the war” for his production of the LCVP (Landing Craft Vehicle Personnel). The National WWII Museum, 2011.065.672.

New Orleans shipbuilder Andrew Higgins would later be credited by General Dwight D. Eisenhower as the “man who won the war” for his production of the LCVP (Landing Craft Vehicle Personnel). The National WWII Museum, 2011.065.672. Motorola manufactured more than 130,000 units of its SCR-536 “Handie-Talkie,” considered the first truly hand-held unit. The SCR-536 was carried by all American infantry units at the Normandy landings and became an iconic symbol of WWII. © Motorola Solutions, Inc., Legacy Archives Collection. Reproduced with permission.

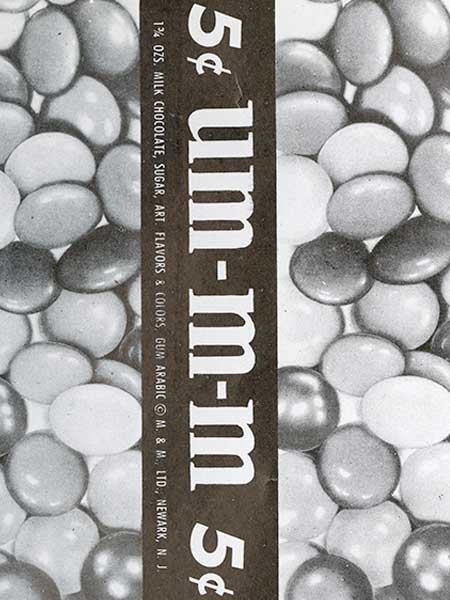

Motorola manufactured more than 130,000 units of its SCR-536 “Handie-Talkie,” considered the first truly hand-held unit. The SCR-536 was carried by all American infantry units at the Normandy landings and became an iconic symbol of WWII. © Motorola Solutions, Inc., Legacy Archives Collection. Reproduced with permission. Patented in 1941, M&M’s hard shell kept chocolate from melting, allowing it to be shipped to the Pacific. M&M's were exclusively sold to the US military during the war, and tubes of M&M's were issued in soldiers’ C-rations. On loan from Mars Incorporated.

Patented in 1941, M&M’s hard shell kept chocolate from melting, allowing it to be shipped to the Pacific. M&M's were exclusively sold to the US military during the war, and tubes of M&M's were issued in soldiers’ C-rations. On loan from Mars Incorporated. -

As a result of these industrial innovations, American wartime production figures were staggering. Tank production alone went from 331 units in 1940 to 29,497 in 1943. The result brought the US from an isolationist nation to a world superpower over the course of a few short, hard years.

Next

-

Share on Facebook

-

Share on Twitter

Tweet -

Share on Tumblr